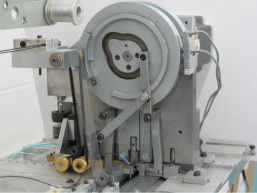

Cam Driven Jumper Head

Here is a cool little fast….This Cam Driven Jumper Head produces staple-shaped SMT jumpers from rectangular copper wire that is plated with nickel. There are four cam surfaces and a three step Geneva index mechanism that are powered by one motor. The wire is fed from the left into a pinch roller that has an adjustable pneumatic force mechanism designed to pinch the wire hard enough to feed it without distorting it. The wire is precisely fed a precision length just below the outside form tool. The downward Z motion cuts the wire on the left with the outside form tool and bends both the left and right sides of the jumper downward around an anvil. The bottom form tools are horizontally driven to bend the protruding wire towards the center to finish the staple-shaped form. The bottom form tools and anvil retract then the outside form tool lowers and places the SMT Jumper in the precision tape pocket directly below the Jumper Head. Because it is all mechanically timed with one power source, the Cam Driven Jumper Head can be run at 15 cycles per second.